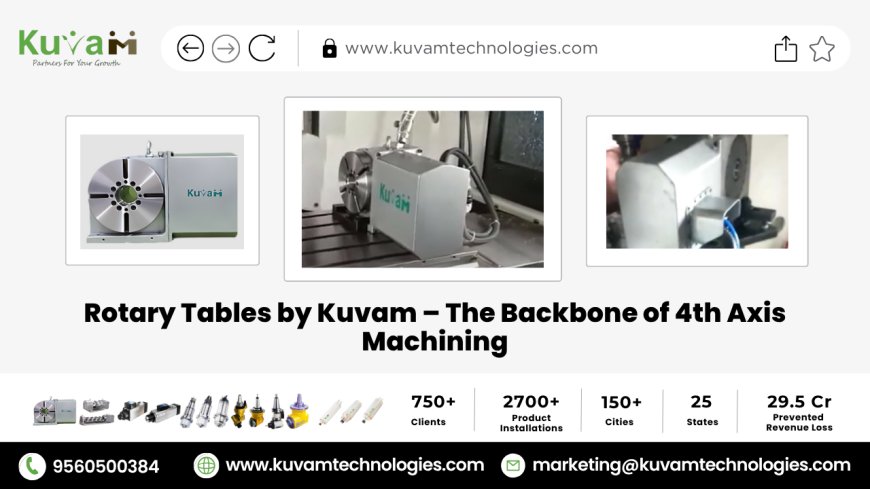

Rotary Tables by Kuvam – The Backbone of 4th Axis Machining

Discover how Kuvam’s Rotary Tables enhance 4th axis machining with precision, speed, and automation. Ideal for CNC VMCs across various industries.

In the race for higher productivity and exceptional accuracy, manufacturers are increasingly turning to advanced technologies. Among the most impactful innovations in CNC automation is the Rotary Table a precision component that enables complex part machining with ease.

Kuvam Technologies brings world-class rotary solutions to the Indian manufacturing sector, helping industries reduce cycle time, eliminate manual errors, and increase spindle utilization. Whether you're a job shop or a large OEM, adding a rotary table to your VMC is the smartest way to stay ahead.

? What Is a Rotary Table and Why Is It Crucial?

A Rotary Table is a precision positioning device that adds rotational movement to a machine tool, effectively introducing a 4th axis into standard 3-axis machining operations. It allows components to be machined from multiple angles in a single setup, improving accuracy and minimizing repositioning.

From slot cutting to helical milling, and circular engraving to gear indexing, a rotary table enhances your shops machining capability exponentially.

?? Kuvam Rotary Tables: Designed for Indian Industry

Kuvams rotary solutions are engineered for performance, reliability, and easy CNC integration. Our range includes:

-

Standard 4th Axis CNC Rotary Table

-

Tilting Rotary Table for 5-axis functionality

-

Hydraulic and Pneumatic Indexing Tables

-

Rotary Production Assemblies for mass production environments

Key features:

-

High torque clamping for heavy cuts

-

Accurate repeatability and rigidity

-

Compact footprint for retrofitting

-

Compatible with major CNC brands like FANUC, Siemens, Mitsubishi

? Why Your VMC Needs a Rotary Table Today

1. Simplify Complex Machining Tasks

Reduce multiple setups and improve part consistency by machining multiple sides in one go.

2. Increase Throughput

A well-integrated rotary table helps achieve shorter machining cycles, especially useful in batch production.

3. Maximize Machine Utilization

Adding a rotary axis allows simultaneous operations, ensuring better VMC productivity and tool efficiency.

4. Enable Multi-Axis Capabilities

With tilting rotary tables, you can perform 5-axis level operations without upgrading your existing machine.

5. Support Automation Goals

Kuvams rotary products are automation-friendly perfect for integration into robotic cells or lights-out manufacturing.

? Industries Using Kuvam Rotary Tables

Kuvams rotary solutions are trusted by 850+ clients in sectors such as:

-

Automobile (engine components, steering knuckles)

-

Aerospace & Defence (aircraft brackets, turbine parts)

-

Medical Equipment (orthopedic tools, implants)

-

Mould & Die Making

-

General Engineering & Tool Rooms

Our rotary tables are installed in over 2800 machines across 170+ cities and growing.

?? Customer Story: From Manual Indexing to Full Automation

One of our clients, a gear manufacturer in Manesar, switched from manual setups to a Kuvam 4th Axis Rotary Table. The result? 50% cycle time reduction and improved part accuracy. This transformation not only increased production but reduced operator fatigue and rework.

? Why Kuvam Is Your Ideal Rotary Partner

Kuvam Technologies isnt just a supplier we are solution providers. With 14+ years of domain expertise, we guide our clients from machine selection to successful integration. Every rotary table is backed by:

-

Fast technical support

-

Spare part availability

-

Customized solutions

-

Robust service network across India

? Conclusion: Modern Machining Demands Rotary Integration

In an era where speed, precision, and flexibility define success, the Rotary Table is more than just an accessory its a necessity. Kuvams rotary solutions are designed to empower manufacturers with automation, efficiency, and confidence.

Upgrade your 3-axis VMC. Add power to your process.

Choose Kuvam Technologies where rotation drives results.

? Contact Us

Want to boost your CNC performance?

? sales@kuvamtechnologies.com

? www.kuvamtechnologies.com